And design stages for a new station. Sales Install Parts Service.

Accurate Pressure Transmitters Mean Trouble Free Gas Pipelines Wika Canada

The EARTHRES team of engineers and technicians provided design services for the modification project that comprised of replacing six 6 100 MMscfd capacity each compressor systems and engineering sizing and designing associated equipment including gas coalescers gas scrubbers and gasgas heat exchangers including all structural support systems and pipe designs.

. Whether your application is upstream at the well pad midstream at your process facility a prime mover in your transmission system or a fuel gas booster for your power plant compression is what moves your product. This nitrogen compressor is a flooded screw design that has a power rating of 2000 HP. The Canadian natural gas pipeline network is comprehensive and does a phenomenal job of transporting natural gas throughout this nation.

CSD can be your compressor station design and management solution. Except for a compressor building on a platform located offshore or in inland navigable waters each main compressor building of a compressor station must be located on property under the control of the operator. Ad Aerzens Intnl Experts Are Skilled In All Areas Of Process Gas Compression Transport.

Neither the CNGVA members of the CNGVA CES or any person acting on behalf of any of the parties mentioned. Natural gas compression is a critical component of any natural gas network. Browse 70 natural gas compressor station stock illustrations and vector graphics available royalty-free or search for natural gas engine or natural gas pipeline to find more great stock images and vector art.

As gas enters the compressor station from the pipeline it passes through a natural gas scrubber vessel. We work with you to develop a compression plan and design that yields the. Oil and gas industry and transportation vector icon set design.

The purpose of compressor stations is to maintain the movement of natural gas along the pipeline. The proposed methodology for determining the individual design alternatives is referred to here as compressor station spacing CSS. The air not into the ground.

Once the natural ga. CES as an account of work sponsored by the Canadian Natural Gas Vehicle Alliance CNGVA. From full permitting through detailed design construction management and commissioningstart-up assistance.

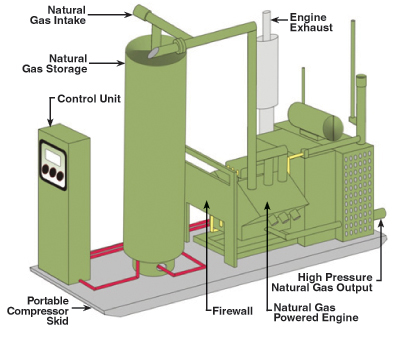

This vessel is designed to remove free liquids dirt or other particulates from the gas stream before it enters the compressors. The station is a Mid-Stream station where Natural Gas is stored until required by market demand. A typical single-stage compressor station design Fig.

Make informed pipeline design decisions. In addition to the Natural Gas compressor system the nitrogen system is the main circulation driver in a closed-loop refrigeration process a modified Carnot Cycle. Water and natural gas liquids removed by the scrubber are sent to a double-walled holding tank for.

Design of compressed natural gas CNG fueling stations require the skills of mechanical electrical structural and civil engineers as well as architects and surveyors. This small CNG Station has only 2 connections Inlet gas connection and 460V3 PH to the motor starter box and is ready to use for natural gas refueling. Small Natural Gas Compressor station designed for small smart fleets.

192163 Compressor stations. Perfect for the smart business that is ready for natural gas refueling at a smaller scale. Natural Gas Compression Packages.

Manufacturer Of Blowers Compressors Used For Air And Gas Applications Around The World. Natural gas enters a compressor station through station yard piping and is passed through scrubbers and filters to extract any liquids and remove solids or other particulate matter that may be in the gas stream Figure 1. CSD Engineers has been involved in all phases of compressor station design in the transmission and gathering segments of the shale gas plays in the tri-state area.

Diaphragm compressor used to compress hydrogen gas to 6000 psi 41 MPa for use in a prototype compressed hydrogen and compressed natural gas CNG fueling station built in downtown Phoenix Arizona by the Arizona Public Service company an electric utilities company. A Location of compressor building. Each layer of steel casing is cemented into place to create a.

1 may consist of an inlet scrubber to collect entrained liquids ie water corrosion inhibitors andor hydrocarbon liquids that may have formed in the gas transmission pipeline followed by a coalescing filter to remove fine solids ie pipe scale and hydrocarbon mist from the gas that could otherwise contribute to compressor. 6 previous slide 1400 compressor stations. 100 Free to Use.

Ad Industrys Trusted Guide For Machinery Parts Supplies Services. The Journey of Natural Gas. The natural gas pipeline has over 50000 miles of mainline and other components connected to natural gas production centers places to store the natural gas components and other spaces to connect with.

This report was prepared by Change Energy Services Inc. A typical natural gas well is constructed with 3 million pounds of steel and cement. Gas compressor stations are designed to move gas as opposed to a liquid any gaseous releases from the facility are into.

We were selected by UGI to fast-track full permitting and design services for a 5600-hp compressor facility in Susquehanna County Pennsylvania. Unlike traditional gasoline or diesel fueling facilities CNG stations are not one size fits all primarily due to the available natural gas pressure and volume of gas that. Due to higher than projected production of natural gas from prolific Marcellus Shale wells serving a Fortune 100 firms local manufacturing facility compression is required to move 120MMCF of gas per day outbound to.

Engineering Compressed Natural Gas Fueling Designs. Reciprocating compressors were used to compress the natural gas. Ad Natural Gas Compressor Packages.

To ensure construction activities do not impact water potential water quality impacts are considered during the planning. Compressed Natural Gas and Liquefied Natural Gas Page 2 Disclaimer LEGAL NOTICE. Each design is obtained by placing compressor stations throughout the pipeline in such a way as to satisfy pipeline and compressor constraints.

Oil Gas Compressors. Sales Contract Parts Service. Compressors are used for natural gas gathering transport processing storage and distribution fuel gas US has approximately 1700 midstream natural gas pipeline compressor stations with a total of 5000-7000 compressors US has.

40 Mmscfd Natural Gas Compressor Station Samuel Engineering Epcm

Pipeline And Compressor Station Design And Construction Services Metropolitan Engineering Consulting Forensics Services

What Is A Natural Gas Compressor Station Kb Delta

Natural Gas Compressor Station Flow Measurement Control

Standardize Compressor Station Design To Reduce Project Costs And Time Line

What Is A Compressor Station How Does It Work Ifs Solutions

0 comments

Post a Comment